What's going on: Start to finish

In my compact framebuilding shop (235 square-feet), I build bicycles from the highest quality materials designed to the rider’s body measurements and the bike's intended use. I also build the Farfarer Trailer, the Frances Spatula, and more.

While I have prioritized American-made materials and components, it is not always possible. To be clear, my desire to use American-sourced materials and parts does not stem from nationalist inclinations, but from the physical realities of geography and efficiency. It is a care for energy, efficiency, and conservation . It is much the same romanticism that draws me to bicycles. Eat local. Current framesets are a mixture of Columbus, Vari-Wall and Tange Tubes- all very high quality. Frame fittings and components come from Paragon Machine Works (the best) as well as other suppliers and many small parts are made here in the shop. The Farfarer trailers are now built exclusively with Tange Tubing , of the highest quality.

Modern steel is light and has all the weight, flex and strength characteristics desirable in bicycle performance and is perfect for the Farfarer trailer design.

BICYCLE DESIGN:

Once I know who I am building for (body measurements, needs, desires, terrain. . . a lot of stuff!), Diamond frames are laid out in Bike Cad, a computer drafting program by Brent Curry. Many variables are customized per the riders needs.

This is the frameset I took to the NAHBS (2016). Without a customer for the show bike, I fell back on the assignment of what I want to ride. Compact, short in the toptube for drop-bar fit. I outfitted the frameset with a front rack/bag-support and low-rider panels. I chose 26" wheels because I know they'll roll plenty fast with some supple high-volume tires.

Sample Smallhaul design -- Cargo bikes and anything sightly non-standard is designed in Draftsight, 2-D CAD or with pencil and the Vemco drafting machine on the drafting table. Construction requires drawing multiple views- this is the side view.

Fabrication:

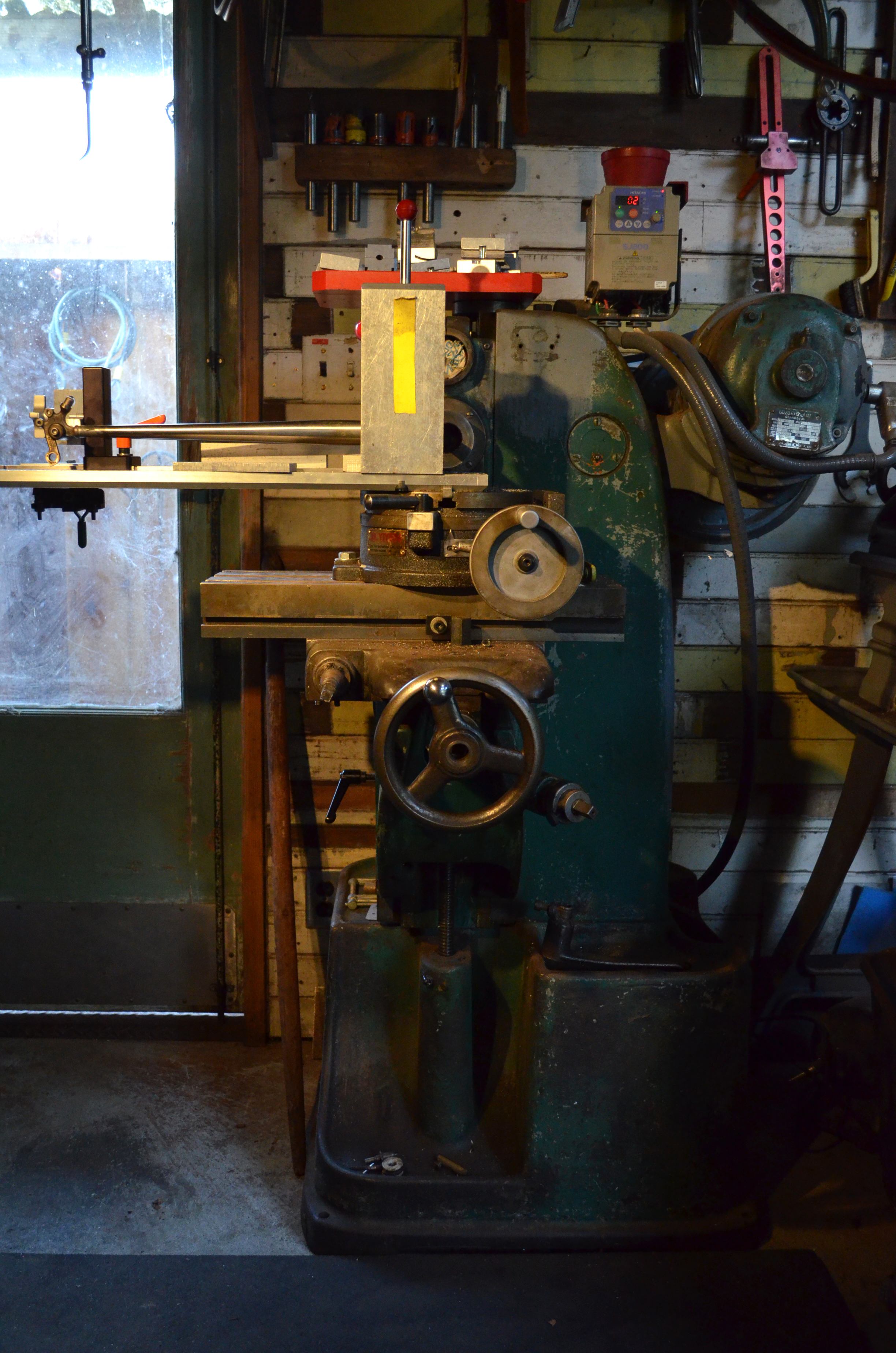

The Nichols hand-miller, made in Waltham, Massachusets, 1943.

Most all main tube mitering is done with the Nichols. A great stout and compact machine.

In addition to holding tube blocks for cutting main tubes, the fixture holds assemblies for cutting stems, chainstays, seatstays, brake posts, and so much more.

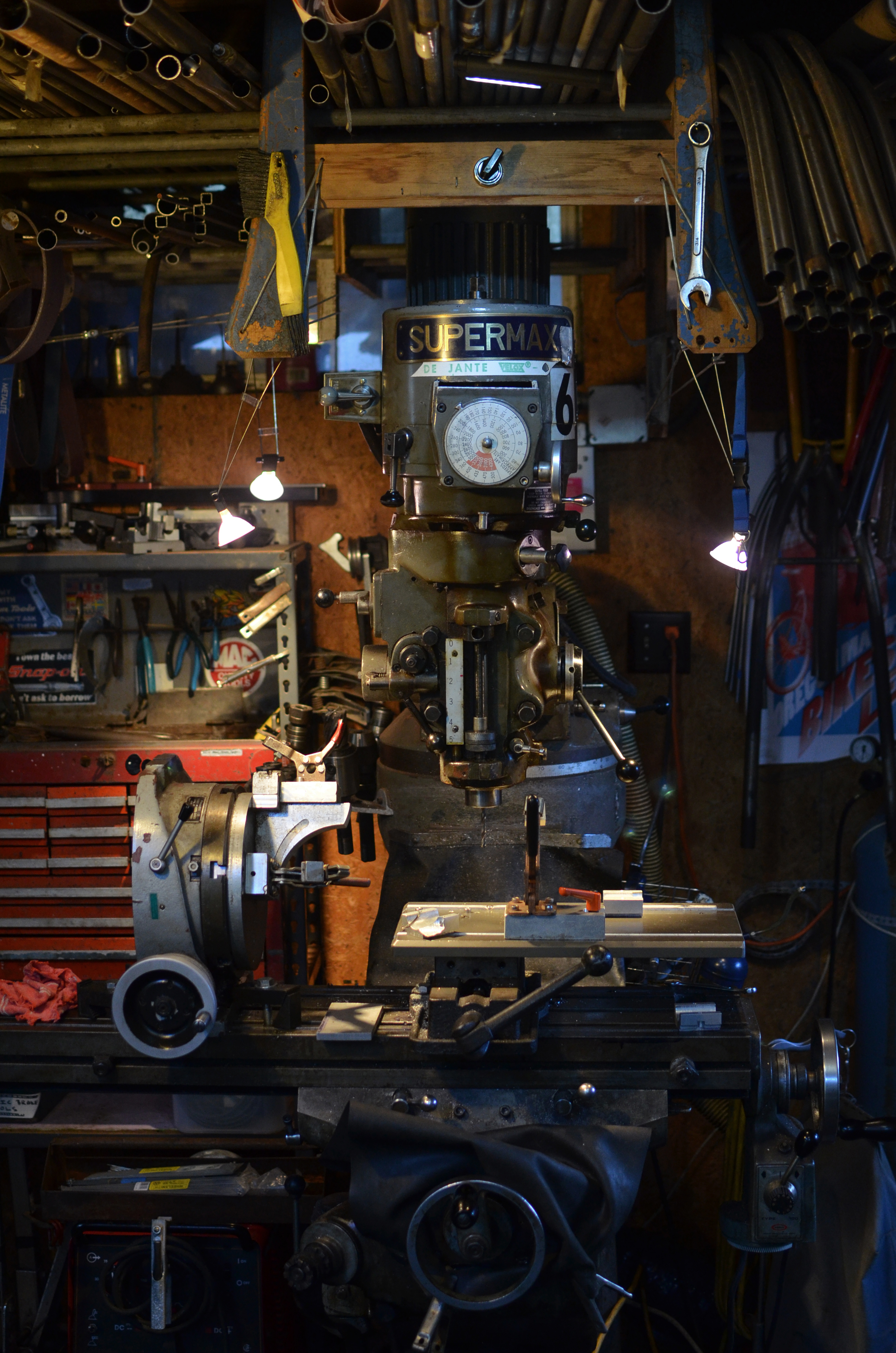

The Supermax, made in Taiwan, 1984

A bridgeport-style vertical milling machine, the Supermax is a vertatile friend.

It drills holes, cuts bridges, shapes aluminium, and is capable of accurately making all kinds of handy shop tools.

Most of my mitering fixtures , bending mandrels and jig assemblies were created with this machine.

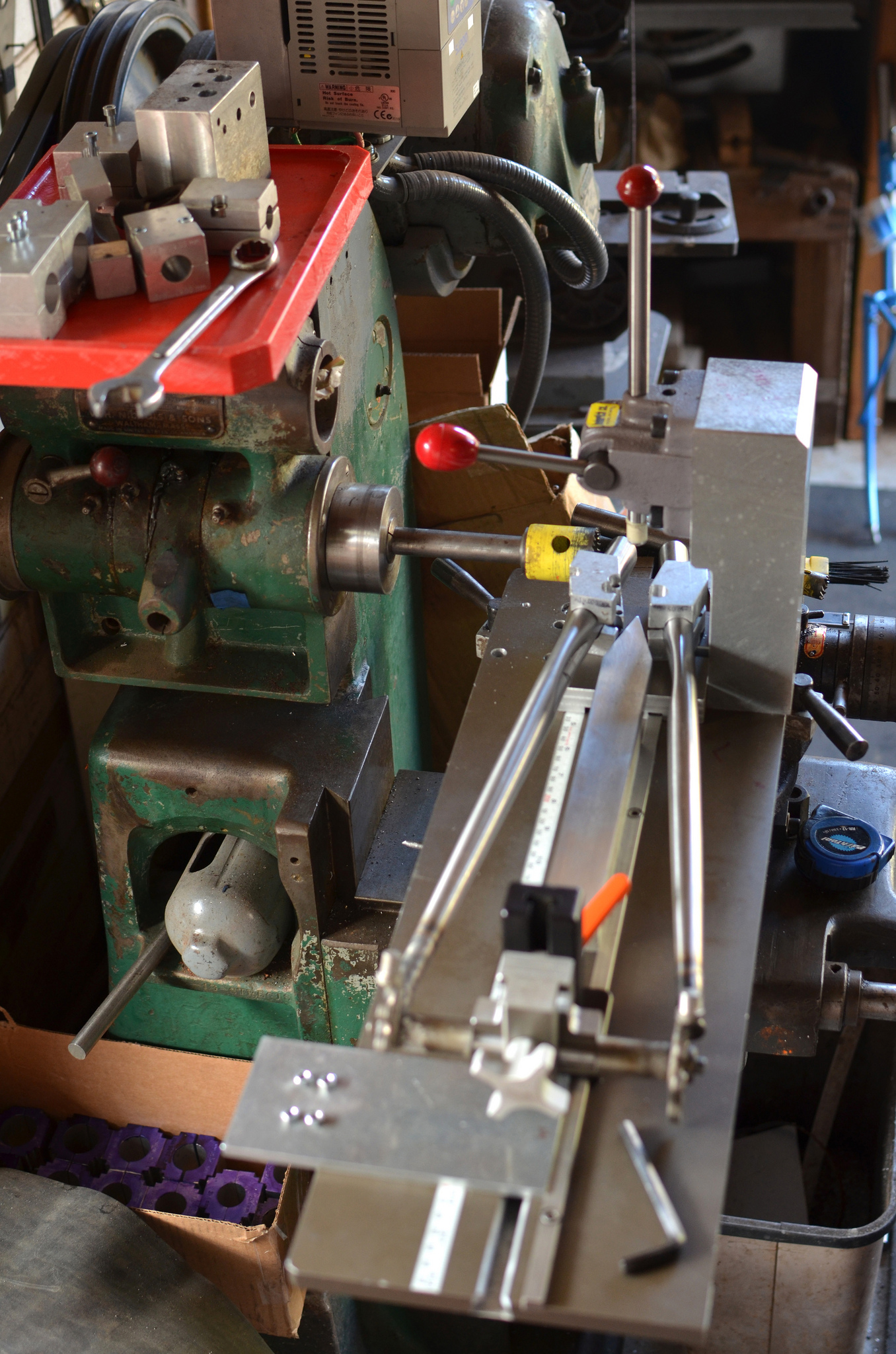

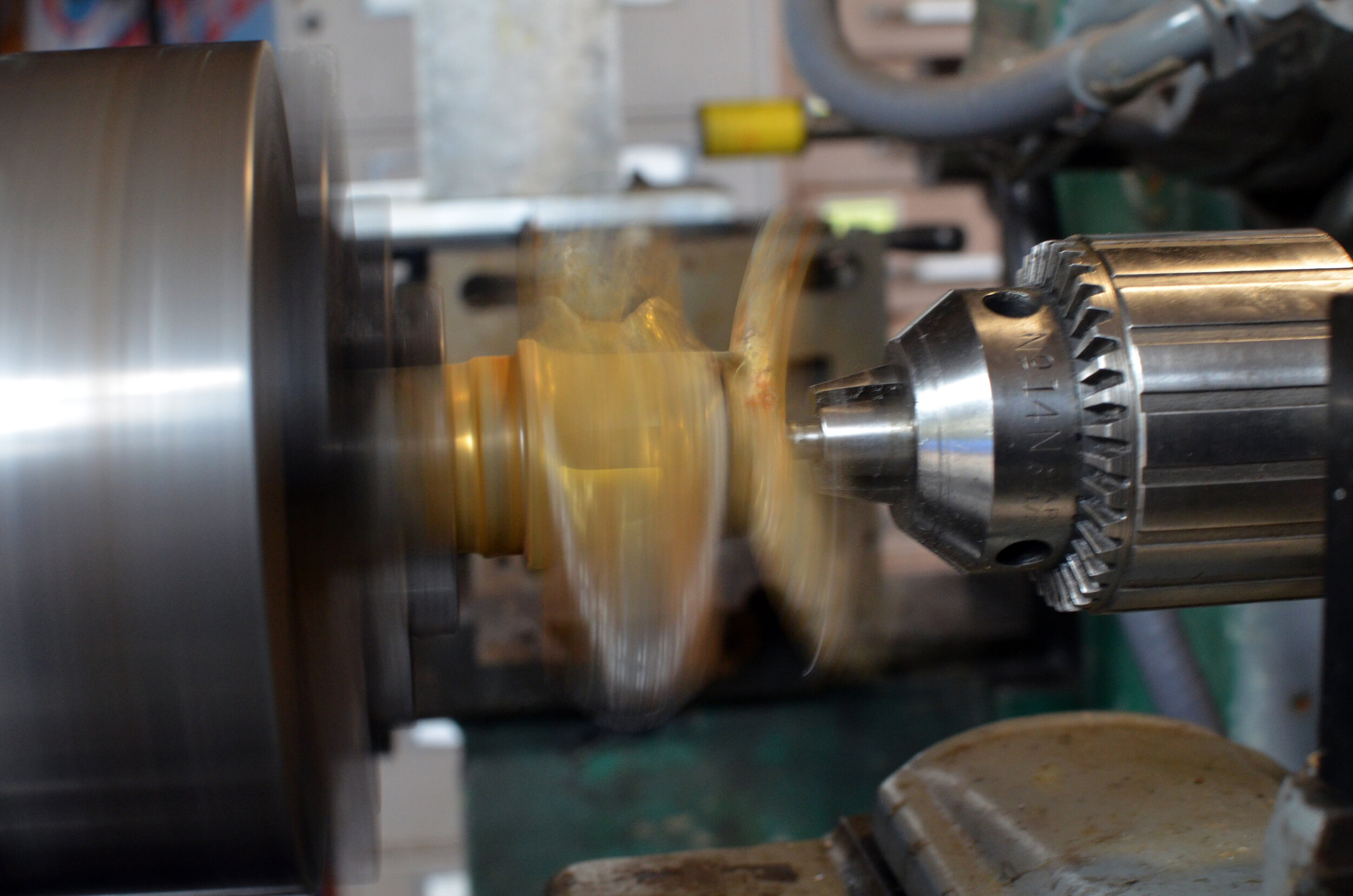

South Bend Heavy 10L Toolroom Lathe, Made in Indiana, 1943.

I bought this machine From Rowe Machinery on the West side of Santa Cruz- Bob and Elaine and their warehouse of machines and tooling is an incredible resource to makers here on the central coast. I wanted something with a big bore that was small enough to fit in the shop and they called when this machine came in. I love it. Accurate, stout, forgiving and friendly. All sorts of things are made with this machine, including all the Farfarer hitch bushings to fit every seat post size out there.

ALIGNMENT:

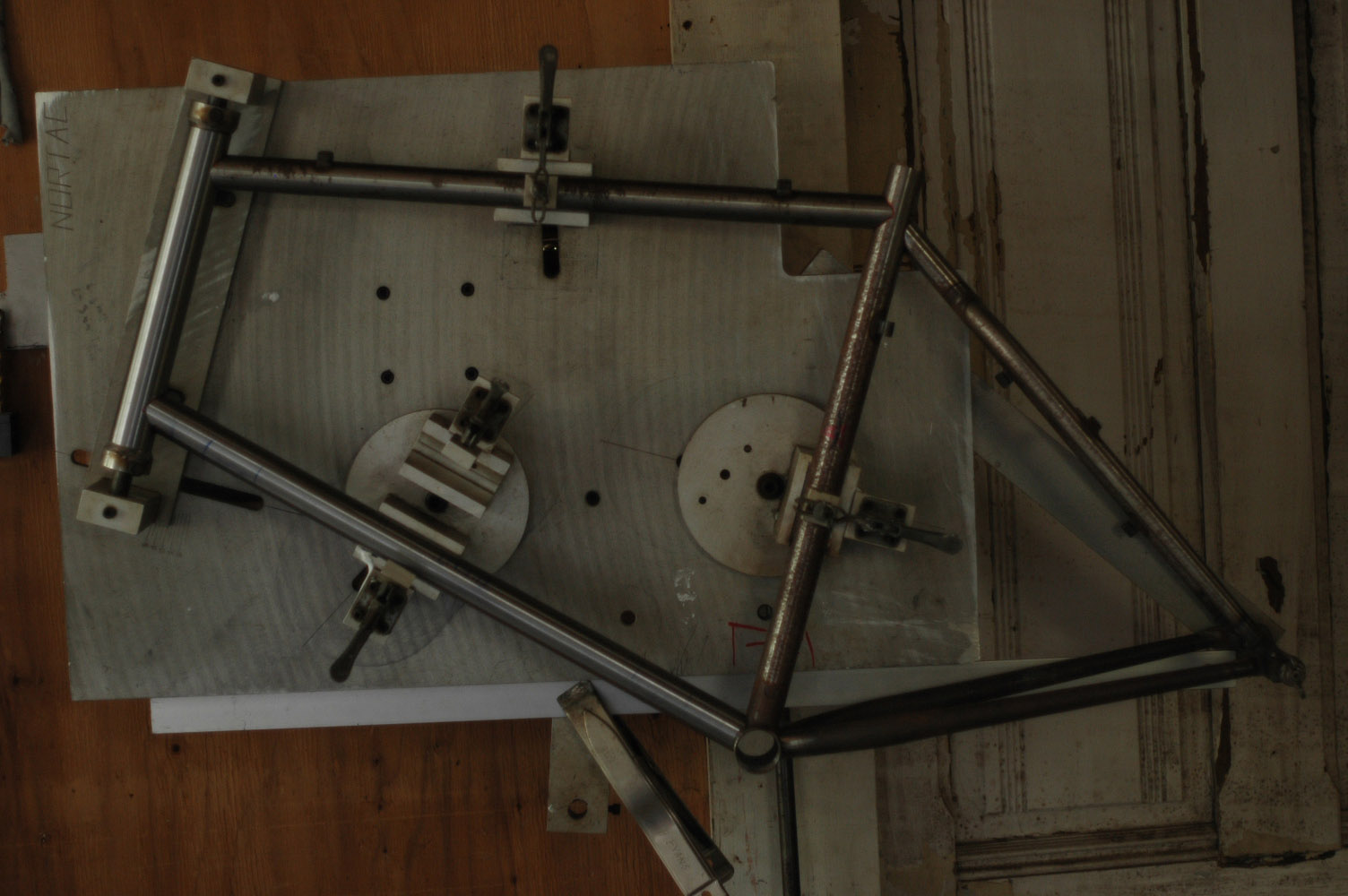

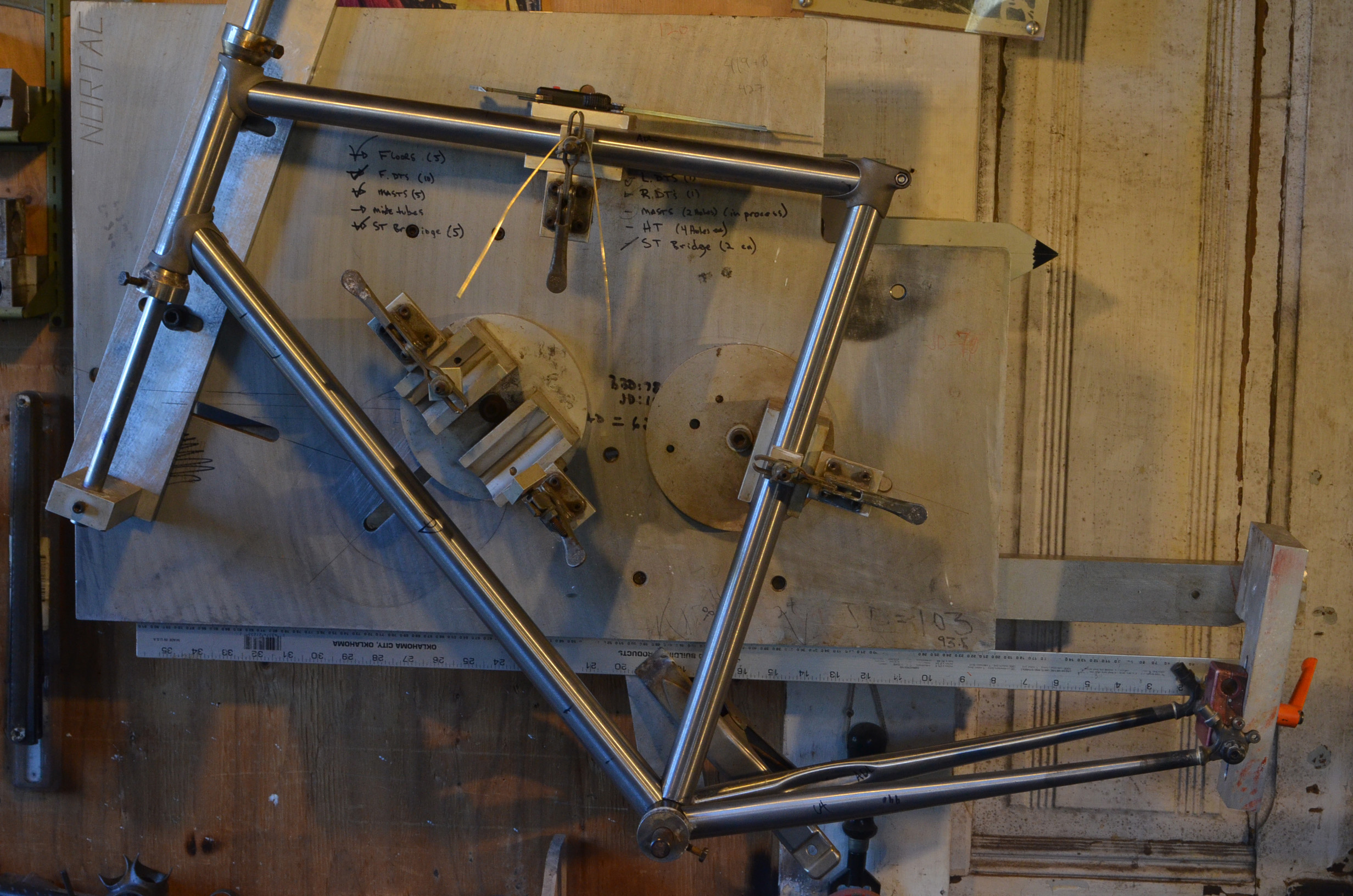

In addition to string and some other basic alignment tools, I rely on a frame alignments table built by NECA (New England Cycling Academy), and a Nortac main frame jig which is constantly rearranged and upgraded to suit the needs of my varied designs. I purchased the NECA from of the illustrious basement of American Cyclery in San Francisco, and the Nortac came from none other than Paul Sadoff of Rock Lobster (selling it at his 2006 NAHBS booth). I also use various tools from J Stein, a mysterious one-off fork jig from the north Bay, and an excellent Journeyman Frame Fixture from Anvil.

SHIPPING:

I make great efforts not to purchase any shipping materials. Bikes are shipped in used boxes from Local Bike Shops (usually The Spokesman- Thanks!) Cargo Bikes that ship in wooden crates are made here from recycled lumber which I compulsively scavenge. I buy trailer boxes (Tharco 36”x16”x7” ) and paper packing tape from Coast Paper supply, conveniently located next to the welding shop, just off the levee.